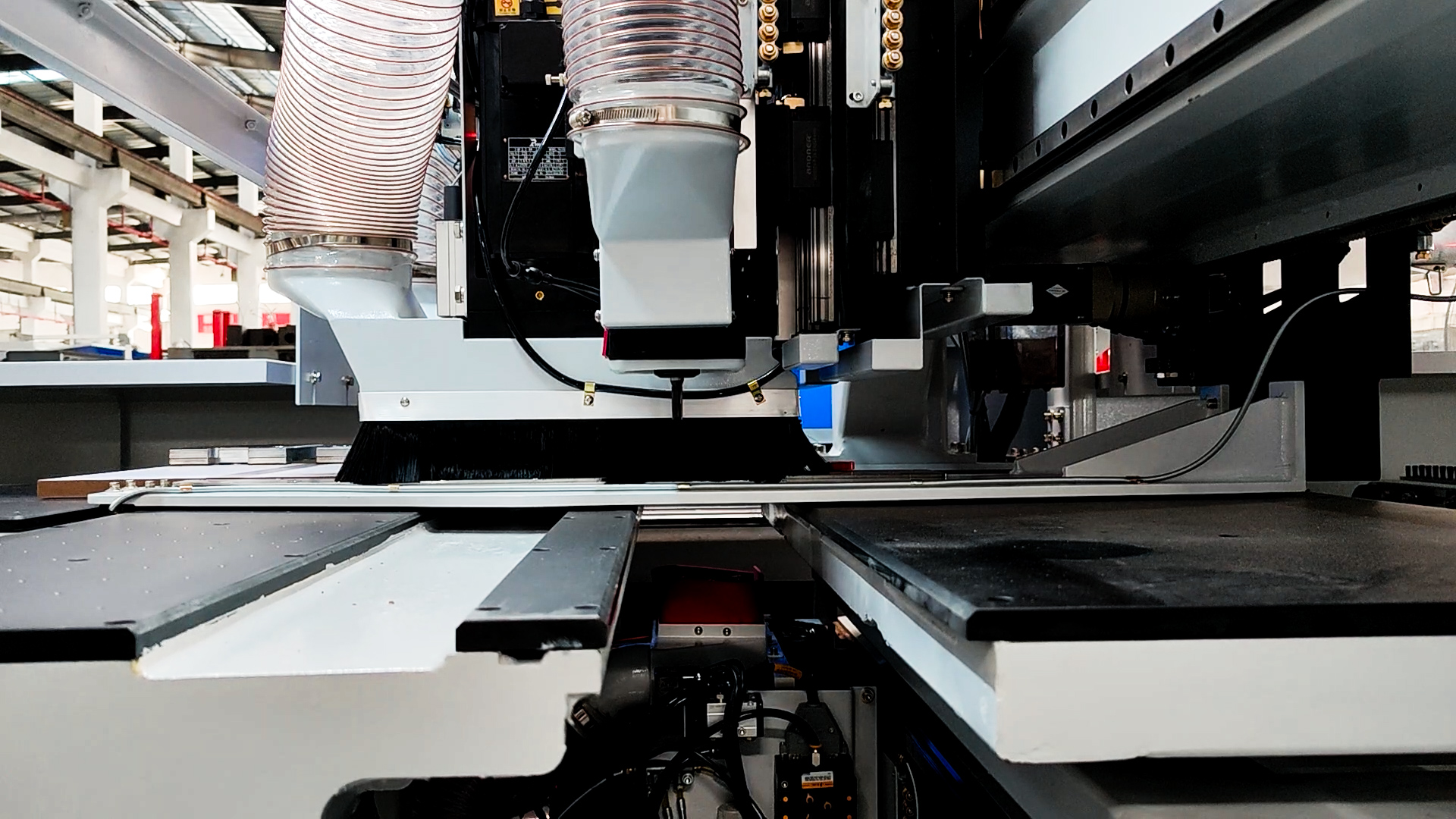

采用德國總線系統(tǒng)

數(shù)控六面鉆�����、三鉆包、雙主軸

Adopt German Bus Control System

6 Sides Drilling,Three Drill Chucks�����、Double Spindles Design

總線系統(tǒng)抗干擾性強(qiáng),采用最優(yōu)加工路徑算法��,一次導(dǎo)入數(shù)據(jù)����,無需翻板,完成六面鉆孔加工���,實(shí)現(xiàn)快速高效鉆孔工作����;

支持掃碼加工�,可與各種品牌生產(chǎn)數(shù)據(jù)軟件無縫對(duì)接;

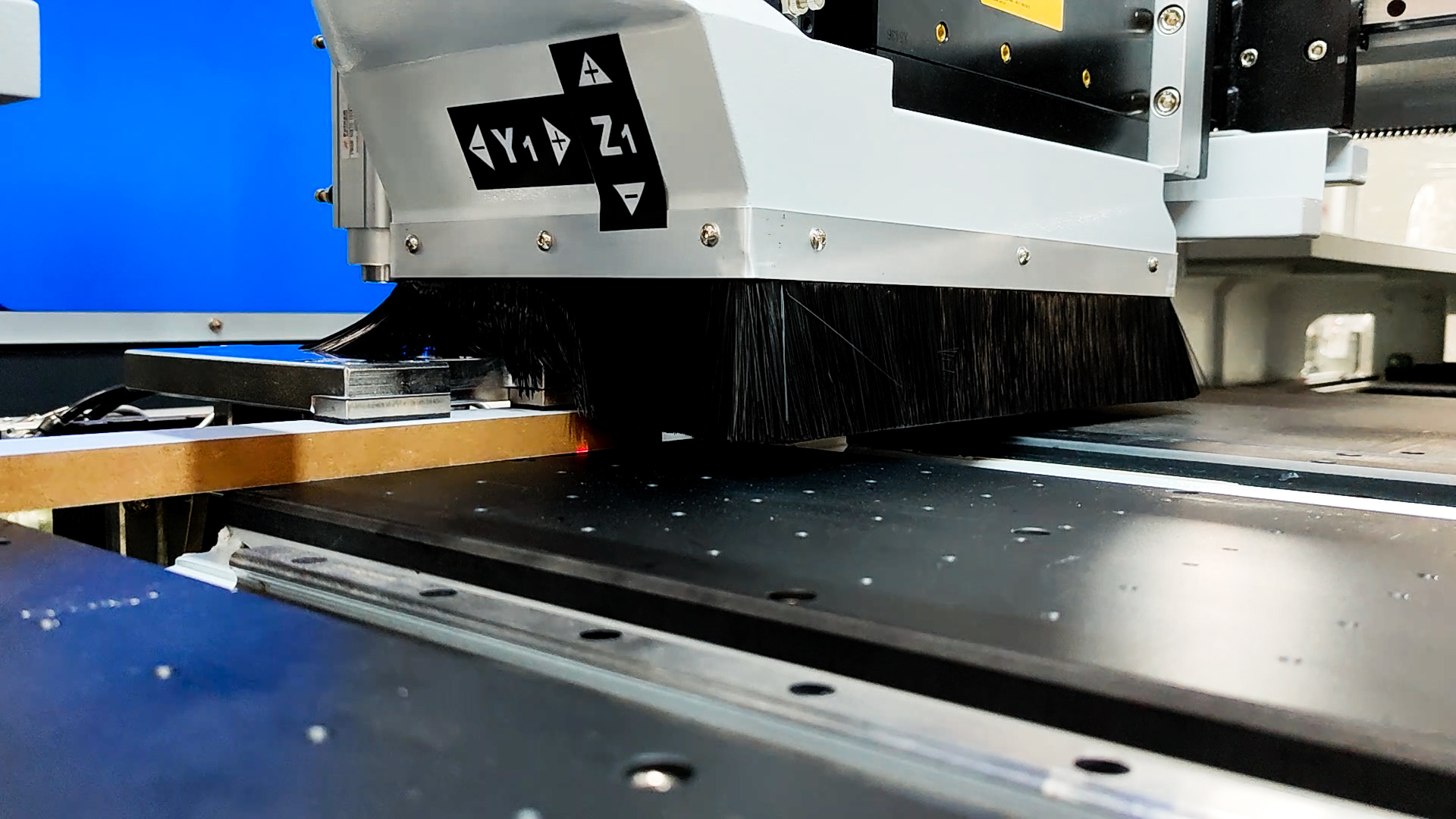

DA-6125L機(jī)械上樑配置雙軸對(duì)稱雙鉆包���,可對(duì)同一工件同時(shí)進(jìn)行同軸孔位的加工����,雙倍提升加工速度�����;

Adopt Bus Controlled CNC System,Optimal machining path algorithm is adopted,data can be one time imported to complete the six sides drilling,to realize fast and efficient drilling work.

Code scan processing and variety brands of production software data are available for connection.

DA-6125 Machinery installed with biaxial symmetric double drill chucks,which can work together for processing the coaxial holes on the same work-piece,double improve the processing speed.

移動(dòng)式氣墊工作臺(tái)

| 技術(shù)參數(shù) |

DA-6125L |

| 各軸行程與最高定位速度 |

| X 軸 |

X1/X2:2930mm,130m/min

|

| Y 軸 |

Y1/Y3:1500mm,110m/min

Y2:1350mm,110m/min

|

| Z軸 |

Z1/Z2/Z3:100mm,60m/min |

| U軸 |

U:1190mm,90m/min |

| 上鉆孔組合裝置 |

| 鉆孔裝置數(shù)量 |

2 |

| 垂直鉆 |

(5X+4Y)x2 |

| 水平鉆 |

(2L+2R+2F+2B=8)x2 |

| 鉆組電機(jī)功率 |

2x2.2KW����,4500rpm |

| 下鉆孔組合裝置 |

| 垂直鉆 |

7鉆軸+1托盤 |

| 鉆組電機(jī)功率 |

2.2KW����,4500rpm |

| 銑型加工主軸 |

| 銑刀數(shù)量 |

2 |

| 主軸形式 |

開槽&銑型 |

| 刀具直徑 |

Ф6-Ф12mm(刀具可選) |

| 刀柄直徑 |

1/2 |

| 加工尺寸范圍 |

| 板材最小寬度 |

35mm

|

| 板材最大寬度 |

1200mm

|

| 板材最小長度 |

250mm

|

| 板材最大厚度 |

60mm

|

| 其他參數(shù) |

| 工作臺(tái)高度 |

950mm |

| 總功率 |

21KW |

| 工作電壓 |

380V�����,50HZ |

| 工作氣壓 |

0.6-0.8Mpa |

| 外形尺寸 |

5400X2800x2300mm |

| 機(jī)械重量 |

4000KG |

| 吸塵口尺寸 |

Ф200mmX1�,Ф120mmX2 |

三鉆包、雙主軸設(shè)計(jì)

Three Drill Chucks, Double Spindles Design.